Audit of RCMP Facilities Management: Health and Safety

Final report

July 2022

On this page

- Acronyms and abbreviations

- Executive summary

- Management's response

- 1 Background

- 2 Objective, scope and methodology

- 3 Observations

- Appendix A – Audit objective and criteria

- Appendix B - Management action plan

Acronyms and abbreviations

List of acronyms used:

- BMP

- Building Management Plan

- CM&C

- Corporate Management and Comptrollership

- DHSC

- Divisional Health and Safety Committee

- HR

- Human Resources

- NHQ

- National Headquarters

- NPHSC

- National Policy Health and Safety Committee

- NSCC

- National Service Call Centre

- O&M

- Operations and Maintenance

- OHSB

- Occupational Health and Safety Branch

- OSO

- Occupational Health and Safety Officer

- OSM

- Occupational Safety Manual

- PMM

- Property Management Manual

- PSPC

- Public Services and Procurement Canada

- RCMP

- Royal Canadian Mounted Police

- RPMB

- Real Property Management Branch

- TOR

- Terms of Reference

- WPHSC

- Workplace Health and Safety Committee

- WPHSC/R

- Workplace Health and Safety Committee and Representative

- WPHSR

- Workplace Health and Safety Representative

Executive summary

Background

The Royal Canadian Mounted Police (RCMP) manages one of the largest real property portfolios in Canada. Its facilities include detachments, houses, headquarters buildings, offices, forensic laboratories, firing ranges and training sites. Some of these facilities are owned and occupied by the RCMP, while others are occupied by the RCMP, but owned and operated by other parties such as other federal departments, municipalities, First Nations, and private landlords. The health and safety of employees in the workplace is a priority of the RCMP.

The RCMP Property Management Manual (PMM) contains policy guidance to ensure that facilities are safe, healthy, support operations, and meet the requirements of the Canada Labour Code and Treasury Board of Canada. Facility management services are provided through the RCMP in-house real property program and third party contractors to meet these legislative and policy requirements. These services include operating, monitoring and maintaining buildings, conducting environmental testing to identify and remediate health and safety hazards, and managing construction projects over the lifecycle of a building.

The Canada Labour Code Part II gives RCMP management and employees the joint responsibility for worker safety, while at their workplace. The RCMP Occupational Safety Manual (OSM) contains policy guidance to assist employees in the performance of their safety-related responsibilities. In accordance with the Canada Labour Code, the RCMP has established a National Policy Health and Safety Committee (NPHSC), Divisional Health and Safety Committees (DHSC)s, Work Place Health and Safety Committees (WPHSC)s for buildings where there are 20 or more employees, and identified Work Place Health and Safety Representatives (WPHSR)s in workplaces with less than 20 individuals.

Why this is important

The RCMP manages one of the largest and most diverse real property portfolios in Canada and relies on multiple stakeholders to keep facilities safe and in compliance with health and safety requirements. Stakeholders need to effectively collaborate with one another to identify, prevent, and respond to health and safety risks and incidents in an appropriate manner.

Audit objective and scope

The objective of the audit was to assess the adequacy of the RCMP facilities management framework in ensuring the health and safety of employees. The scope of the audit focused on the facilities management framework in place to identify and address environmental health and safety issues for the period of April 1, 2018 to June 30, 2020. The audit included an assessment of the processes established to identify and mitigate environmental health and safety risks within various types of facilities. While the audit did not directly assess the adequacy of funding and resources to support the facilities management framework in ensuring the health and safety of employees, it is acknowledged that the level of resourcing available to business lines and policy centres impacts the organization's ability to address the audit's findings and recommendations.

Depot Division was excluded from the scope due to its unique facilities management model where services are provided by full-time RCMP employees instead of contractors.

The audit also did not include assessing processes in place to respond to the COVID-19 pandemic as a separate assessment on the RCMP's COVID-19 preparedness and response has been conducted by RCMP Internal Audit, Evaluation and Review.

Findings

The following aspects of the facilities management framework related to health and safety require management's consideration. The detailed observations and recommendations are discussed later in the report.

- Observation 1

- The RCMP has established a facilities management framework that takes into consideration occupational health and safety of employees. Opportunities exist to enhance clarity and awareness of roles and responsibilities and improve national guidance related to environmental hazards.

- Observation 2

- The RCMP has processes and procedures in place to identify and mitigate health and safety risks within its facilities. However, the RCMP would benefit from more consistent inspections, environmental testing, and information management to better mitigate health and safety risks to RCMP employees, contractors, and the public.

- Observation 3

- A variety of monitoring mechanisms were in place to track and report on health and safety issues and incidents. Opportunities exist to enhance and standardize the monitoring of workplace inspections to help mitigate the risk that health and safety concerns go undetected.

Overall audit opinion

The RCMP has a facilities management framework in place to ensure the health and safety of employees. The framework includes a governance structure, policies, and roles and responsibilities for a variety of stakeholders that are involved in inspecting for health and safety issues in RCMP facilities, as well as identifying and resolving those issues.

There are opportunities to strengthen the framework through enhancing national guidance, clarifying roles and responsibilities and implementing more effective monitoring. The audit's findings apply to all types of buildings examined with specific exceptions noted where relevant. While roles and responsibilities have been defined at a high level in policy, specific responsibilities related to health and safety hazards in buildings, particularly testing, as well as monitoring and reporting findings for environmental hazards, have not been clearly defined. This increases the risk that inconsistent approaches to testing for health and safety hazards will take place across the RCMP. Limited capacity impacted the ability of the real property program to maintain and apply the PMM and carry out testing for environmental health hazards across the RCMP. As a result, occupants in different parts of the country are potentially exposed to different levels of risk.

Although policy is in place to guide compliance with the Canada Labour Code Part II requirements for occupational health and safety, evidence was not available to confirm that requirements were fulfilled. Workplace Health and Safety Committees and representatives have specific responsibilities related to health and safety in their buildings; however, limited evidence was found that all of these responsibilities were being fulfilled on a consistent basis. The audit also found that monitoring of whether workplace inspections were taking place was limited. In order to effectively identify risks and protect building occupants, all stakeholders in the framework need to fulfill their responsibilities. Conducting and communicating the results of building inspections that identify hazardous building conditions and required maintenance, as well as work place safety inspections play a key role in preventing health and safety issues. Similar to the real property program, limited capacity was noted as a key challenge in this area.

Next steps

The management response and action plan developed in response to this report demonstrate the commitment from senior management to address the audit findings and recommendations. RCMP Internal Audit will monitor the implementation of the management action plan and undertake a follow-up audit if warranted.

Management's response

The Chief Human Resources Officer and Chief Financial Officer agree with the findings and recommendations of the Audit of the RCMP Facilities Management: Health and Safety, which has identified opportunities to enhance clarity and awareness of roles and responsibilities and improve national guidance related to environmental hazards, employ consistency in health and safety risk mitigation practices, and enhance and standardize the monitoring of workplace inspections to mitigate health and safety risks. Additional resources and funding will be required to fully address the requirements within this report.

Nadine Huggins, Chief Human Resources Officer

Jen O'Donoughue, Chief Financial Officer

1. Background

1.1 Audit context

The RCMP manages one of the largest real property portfolios in Canada. The diverse facilities include detachments, houses, headquarters buildings, offices, forensic laboratories, firing ranges and training sites. Some of these facilities are owned and occupied by the RCMP, while others are occupied by the RCMP, but owned and operated by other parties such as other federal departments, municipalities, First Nations, and private landlords.

The health and safety of employees in the workplace is a priority of the RCMP. The RCMP PMM contains policy guidance to ensure that facilities are safe, healthy, support operations, and meet the requirements of the Canada Labour Code, and other applicable legislation and Treasury Board of Canada.

Facility management services are provided through the RCMP in-house real property program and third party contractors to meet these legislative and policy requirements. These services include operating and maintaining buildings, conducting environmental testing to identify and remediate health and safety hazards, and managing construction projects over the lifecycle of a building.

The Canada Labour Code Part II requires RCMP management and employees to share the responsibility for worker safety, while at their workplace. The RCMP OSM contains policy guidance to assist employees in the performance of their safety-related responsibilities. In accordance with the Canada Labour Code, the RCMP has established NPHSC, DHSCs, on-site WPHSCs for buildings where there are 20 or more employees, and identified WPHSRs in workplaces with less than 20 individuals.

The Commissioner approved 2020‑25 Risk-Based Audit and Evaluation Plan which included the Audit of Facilities Management: Health and Safety.

2. Objective, scope and methodology

2.1 Objective

The objective of the audit was to assess the adequacy of the RCMP facilities management framework in ensuring the health and safety of employees.

2.2 Scope

The scope of the audit focused on the facilities management framework in place to identify and address environmental health and safety issues for the period of April 1, 2018 to June 30, 2020. The audit included an assessment of the processes established to identify and mitigate environmental health and safety risks within various types of facilities. While the audit did not directly assess the adequacy of funding and resources to support the facilities management framework in ensuring the health and safety of employees, it is acknowledged that the level of resourcing available to business lines and policy centres impacts the organization's ability to address the audit's findings and recommendations.

Depot Division was excluded from the scope due to the unique facilities management model where services are provided by full-time RCMP employees instead of contractors.

The audit also did not include assessing processes in place to respond to the COVID-19 pandemic as a separate assessment on the RCMP's COVID-19 response has been conducted by RCMP Internal Audit, Evaluation and Review.

2.3 Methodology

The audit was conducted between November 2020 and November 2021. The audit team employed various techniques including interviews, documentation reviews, data analysis, and file testing.

Specifically, the audit team:

- Selected a sample of five divisions (B, D, E, G and National Headquarters) to provide a geographically diverse perspective on the adequacy of the facilities management framework with respect to health and safety in RCMP workplaces and Member housing. Within the selected divisions, a sample was selected to include a cross representation of all categories of facilities and member housing.

- Conducted interviews with key personnel in Real Property Management and Occupational Health and Safety within B, D, E, G and HQ Divisions. These interviews included senior management in the Division, Occupational Health and Safety Officers, members of Work Place Health and Safety Committees, Regional Directors of Real Property, Asset Managers, Environmental Specialists and members of units identified as being at higher risk of encountering health and safety hazards due to the nature of their activities in RCMP facilities.

- Reviewed information obtained by questionnaire from a sample of detachment commanders from B, D, E and G Divisions.

- Reviewed documentation and supporting evidence to validate information provided in interviews and determine compliance with RCMP policy requirements.

Detailed criteria are contained in Appendix A of this report.

2.4 Statement of conformance

The audit engagement conforms to applicable standards in the Institute of Internal Auditor's International Professional Practices Framework and the Treasury Board of Canada Directive on Internal Audit, as supported by the results of the quality assurance and improvement program.

3. Observations

3.1 Governance

- Observation

- The RCMP has established a facilities management framework that takes into consideration occupational health and safety of employees. Opportunities exist to enhance clarity and awareness of roles and responsibilities and improve national guidance related to environmental hazards.

Key Stakeholders for health and safety in facilities

The RCMP manages one of the largest real property portfolios in Canada. The diverse facilities include detachments, houses, headquarters buildings, offices, forensic laboratories, firing ranges and training sites. Some of these facilities are owned and occupied by the RCMP, while others are occupied by the RCMP, but owned and operated by other parties such as other federal departments, municipalities, First Nations, and private landlords.

The management of health and safety in RCMP facilities involves various stakeholders, including: Real Property; Occupational Health and Safety; and Divisional Management and Work Place Health and Safety Committees and Representatives (WPHSC/R)s. Summarized below are the roles and responsibilities of the various stakeholders which are relevant to the scope of the audit.

Real Property Management Branch (RPMB): The Real Property Management Branch (RPMB) in Corporate Management and Comptrollership (CM&C) is responsible for planning, coordinating, monitoring, controlling, and reporting for all RCMP real property. Asset Managers are responsible for maintaining RCMP buildings, including performing assessments of building condition to identify necessary repairs and maintenance. Depending on the division and specific building, this role can involve procuring and working with third party service providers. In addition, RCMP Environmental Specialists perform testing or develop contracts for the testing of various environmental health hazards in RCMP buildings such as radon, asbestos and potable water contaminants.

Occupational Health and Safety: The Occupational Health and Safety Branch (OHSB) in Human Resources (HR) is the policy owner for the Occupational Safety Manual (OSM) and responsible for promoting a work environment that integrates health and safety best practices into everyday activities. Part of OHSB's role is to identify and ensure the requirements outlined in the Canada Labour Code Part II and other OHS legislation are reflected in RCMP policies. This includes ensuring managers understand their responsibility for the health and safety of all RCMP employees; helping detect, control and resolve occupational safety issues; facilitating policy implementation; and developing strategies to improve compliance with the Canada Labour Code. Each Division has an Occupational Safety Unit dedicated to their respective Divisions.

Division Management, WPHSCs and Occupational Safety Officers: Division Commanding Officers are responsible for ensuring that a DHSC is in place and functioning as per the OSM to coordinate divisional health and safety issues. The DHSC is the principle forum for employee-employer consultation on divisional occupational health and safety issues, and the development of solutions to these issues within each division.

Occupational Safety Officers (OSO) within Divisions provide advice and guidance on internal Occupational Health and Safety policies and application of the Canada Labour Code and its applicable regulations. They provide technical advice to management, employees and health and safety committees. In collaboration with committees and managers, they perform: safety training, accident investigations, work refusals, and complaint investigations. In addition, they help management and committees with workplace inspections, risk assessment and fire safety.

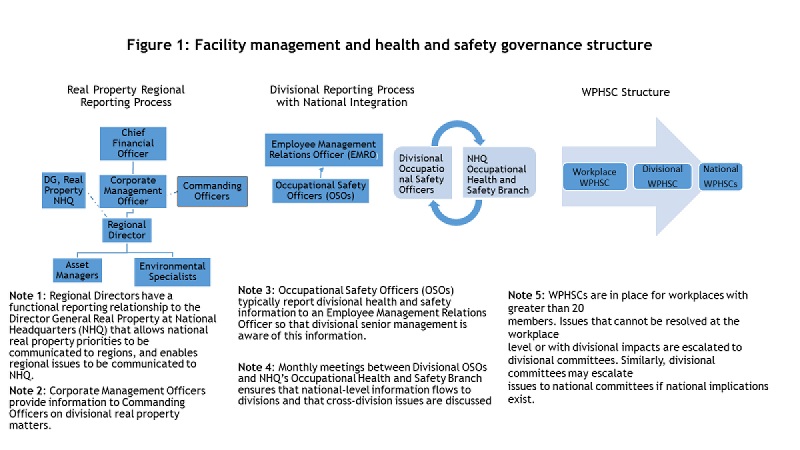

A summary of the overarching governance structure is provided in Figure 1

Facility management and health and safety governance structure - Text version

The first image depicts the Real Property Regional Reporting process.

The boxes identify the following positions and their reporting relationships. Starting from the bottom boxes, Asset managers and environmental specialists report to the Regional Director. The Regional Director reports to the Corporate Management Officer in their region and also has a functional reporting relationship to the Director General, Real Property. The Corporate Management officers report to the Chief Financial Officer, while also having a reporting relationship to the Commanding Officers in their divisions.

Under the image depicting the Real Property Regional Reporting process are two notes. The first note has the following text: "Regional Directors have a functional reporting relationship to the Director General Real Property at National Headquarters (NHQ) that allows national real property priorities to be communicated to regions, and enables regional issues to be communicated to NHQ." The second note has the following text: "Corporate Management Officers provide information to Commanding Officers on divisional real property matters."

The second image depicts the Divisional Reporting Process with National Integration.

The boxes identify the reporting relationships of Occupational Safety Officers. Starting from the bottom left, the Occupational Safety Officers report to Employee Management Relations Officer. In addition, the divisional Occupational Safety Officers in the divisions and National Headquarters Occupational Health and Safety Branch communicate with each other.

Under the image depicting the Divisional Reporting Process with National Integration are two notes. The first note has the following text: "Occupational Safety Officers (OSOs) typically report divisional health and safety information to an Employee Management Relations Officer or Criminal Operations Officer so that divisional senior management is aware of this information." The second note has the following text: "Monthly meetings between Divisional OSOs and NHQ's Occupational Health and Safety Branch ensure that national-level information flows to divisions and that cross-division issues are discussed. NHQ's OHSB is led by the Director General, OHSB, who reports to the Chief Human Resources Officer."

The third image depicts the Workplace Health and Safety Committee Structure.

The boxes identify the reporting relationships between the tiers of health and safety committee. Starting form the left, the Workplace Health and Safety Committees report to the Divisional Health and Safety Committees. The Divisional Health and Safety Committees report to the National Policy Health and Safety Committees.

Under this image is a note with the following text: "WPHSCs are in place for workplaces with greater than 20 members. Issues that cannot be resolved at the workplace level or with divisional impacts are escalated to divisional committees. Similarly, divisional committees may escalate issues to national committees if national implications exist."

Health and Safety Policies

The two primary sources of internal policy related to health and safety within facilities are the PMM and the OSM. The PMM identifies various responsibilities for Real Property related to maintaining and managing RCMP facilities, including the planning, acquisition, operations and maintenance and disposal of these assets. The OSM provides information on various health and safety activities to ensure compliance with the Canada Labour Code Part II.

Property Management Manual

Roles and responsibilities in the PMM are not fully defined. The PMM includes some guidance on roles and responsibilities; however, not all of these roles and responsibilities were fully defined. For example, the PMM noted that National Headquarters (NHQ) is responsible for providing guidance and processes, while regions are responsible for implementing their own Real Property Program in accordance with TB policy and RCMP Directives. The audit noted that a chapter defining specific roles and responsibilities for real property staff in relation to health and safety was being finalized but had not yet been put in place prior to the conclusion of the audit. Limited additional guidance was in place, particularly in relation to responsibilities related to potable water and environmental health hazards. Interviews with regions identified that only Atlantic region had formal, documented guidance in place to define roles and responsibilities related to testing for asbestos and radon, and for testing for potable water contaminants. Interviews with Asset Managers and Environmental specialists in other regions noted that while testing was taking place, roles and responsibilities related to environmental testing were not clear and had not been formally defined.

Information related to environmental hazards in the PMM is limited. Part 7 – Operations and Maintenance (O&M) of the PMM identified various O&M activities including the requirement to provide potable water to all buildings occupied by the RCMP and how environmental health hazards should be handled. However, the level of detail of this guidance is limited and the PMM does not clearly specify the environmental health hazards that should be assessed, or the testing requirements. While interviews with the policy centers noted there is a Wiki* page to support the policy, it was not always linked to the policy and the information on the wiki is not always complete and under development.

*A Wiki is a site that is designed for groups of people to quickly capture and share information.

National guidance to support the PMM is limited. Interviews with Regional Directors, Asset Managers and Environmental Specialists identified a lack of clarity on processes, accountabilities and roles and responsibilities related to environmental hazards. All regions identified that there is a lack of guidance in policy on how to address environmental hazards e.g. hazards to test for, the frequency of testing required, and formal steps to take when hazards are identified. National guidance is under development for asbestos, potable water and radon, but was still in draft form. The responsible policy centre noted challenges such as resource limitations, operational responsibilities and other competing priorities as factors that have limited their ability to complete this guidance.

Occupational Safety Manual

While roles and responsibilities are defined in the OSM, challenges were identified with stakeholders' awareness. The OSM defined roles and responsibilities for the various stakeholders involved with activities related to maintaining compliance with the Canada Labour Code Part II. This includes having WPHSC/Rs, implementing a Hazard Prevention Program, and recording and reporting health and safety incidents. The OSM identified that both employees and employer are responsible for health and safety, with specific employer responsibilities being noted along with various supporting tasks to be carried out by OSOs.

During interviews with OSOs in each Division it was noted that these responsibilities were clear and understood; however, awareness issues were identified with other stakeholders in the process. In a questionnaire sent to a sample of 20 detachment commanders 8 of 20 respondents (40%) indicated that they did not believe that their roles and responsibilities related to health and safety in facilities were clearly defined or they were not aware of these responsibilities (figure 2). Responses indicating a lack of awareness of roles and responsibilities corresponded with smaller detachments that would not have the support of a WPHSC.

| Clearly defined | Unclear/unaware | |

|---|---|---|

| Percentage | 60 | 40 |

Employee Housing

There is limited information in the PMM and the OSM with respect to the health and safety in RCMP housing. Chapter 8.1 of the PMM, Living Accommodation Program denotes when accommodations will be provided and identifies Real Property's responsibilities to manage living accommodations as assets. However, the policy does not go into detail on what is required from a health and safety perspective or the associated roles and responsibilities. As a result, it was not clear which RCMP policies applied from a health and safety perspective with respect to living accommodations or what actions Asset Managers were responsible for carrying out. As RCMP housing is not defined as a workplace, it is unclear which elements, if any, of the OSM would be applicable. This increases the risk that inconsistent approaches will be taken for inspections and environmental testing related to Member housing.

Conclusion

The RCMP has established a facilities management framework that takes into consideration the occupational health and safety of employees. This framework includes a governance structure with NHQ and senior management in Divisions, as well as Corporate Management and Comptrollership and Occupational Health and Safety. Policy is in place to support healthy and safe workplaces in RCMP facilities and includes information on roles and responsibilities.

While a framework is in place, there are opportunities to better clarify governance, monitoring and roles and responsibilities of the various parties involved in the process, particularly in relation to testing for environmental hazards. National guidance on environmental hazards, such as identifying specific hazards that should be tested for, and testing frequency, would enhance clarity around environmental testing and increase consistency in testing across the RCMP.

Why these findings are important

Responsibilities related to health and safety are distributed across multiple business lines. Clarifying and communicating roles and responsibilities would enable stakeholders to understand and fulfill their health and safety responsibilities, avoid operating in siloes, and work together in a more complementary fashion. National guidance is a key component of defining expectations at the organization-wide level when clarity is not provided by policy.

Without consistency, regions may not test for all relevant hazards, or substantially different approaches to testing may be undertaken, resulting in health and safety inequities between regions. In addition, a lack of testing limits management's ability to assess the risk level of environmental hazards and make informed decisions to address them.

Recommendation 1

The Chief Financial Officer, Corporate Management and Comptrollership, in consultation with Occupational Health and Safety Branch, should enhance policy and national guidance related to environmental health hazards by:

- defining which environmental hazards should be monitored.

- clarifying testing requirements for RCMP facilities, including housing (e.g. methodology, frequency, and communication of results).

- communicating changes in policy to relevant stakeholders to ensure roles and responsibilities are clearly understood.

3.2 Processes and Procedures

- Observation

- The RCMP has processes and procedures in place to identify and mitigate health and safety risks within its facilities. However, the RCMP would benefit from more consistent inspections, environmental testing, and information management to better mitigate health and safety risks to RCMP employees, contractors, and the public.

Work Place Health and Safety Committees

The audit found that defined processes and requirements for work place health and safety committees and representatives exist. The OSM Chapter 2 – Health and Safety Committees requires that all workplaces of 20 or more employees establish a WPHSC. Workplaces with less than 20 occupants require that there be a Work Place Health and Safety Representative. The OSM also requires that WPHSCs have formalized Terms of Reference (TOR) and meet at least 9 times annually. Health and safety incidents which occur in their workplace are to be reviewed by the WPHSCs to identify how they can be prevented where possible and that facilities are inspected on a monthly basis.

The majority of WPHSCs had evidence of regular meetings and had a TOR which aligned with the OSM. To assess whether processes and procedures related to WPHSC/Rs were being followed, the audit team selected a sample of 50 facilities, 25 of which were facilities requiring WPHSCs and 25 which required WPHSRs. For the sample with WPHSCs, documentation was requested to support that a TOR was in place and meetings were taking place as required. A summary of the various testing for WPHSC compliance with the OSM is included in Figure 3 below. In some cases, Asset Managers attended WPHSCs in an advisory capacity; however, Asset Managers stated during interviews that due to the size of their assigned building portfolios they were not able to attend every WPHSC meeting.

A significant number of facilities did not have documentation to support that work place inspections were completed in line with OSM requirements. Chapter 12 of the OSM requires that both workplaces with a WPHSC as well as those with a WPHSR carry out inspections of the workplace to identify potential health and safety hazards. As such, documentation to support that these inspections took place was requested from both the WPHSCs and WPHSRs. The audit team's analysis of 50 items in the sample determined that in general, facilities requiring a WPHSC had a higher likelihood of completing inspections as opposed to those facilities without a WPHSC. Compliance testing results for inspections is also presented in Figure 3 below.

| % Compliant | Results for key policy requirements |

|---|---|

| 64% | 16/25 WPHSCs had a TOR in place which aligned with OSM |

| 96% | 24/25 WPHSCs were meeting regularly throughout the year |

| 44% | 11/25 WPHSCs had met the required 9 times a year |

| 60% | 15/25 WPHSCs were conducting inspections |

| 12% | 3/25 WPHSRs were conducting inspections |

Hazard identification and communication

A National Service Call Centre (NSCC) is in place to report hazards identified in some RCMP facilities. RCMP buildings and facilities in regions covered by Public Services and Procurement Canada (PSPC) property management and project delivery services contracts have access to the NSCC. This allows building occupants to report property maintenance concerns including any identified health and safety hazards. The system results in a ticket being produced by the call centre and communicated to the Asset Manager as well as any relevant service providers required to address the issues. However, while this provided a method for occupants to report and track issues until they are addressed, the NSCC is not available for all RCMP buildings. In RCMP owned facilities without access to the NSCC, issues need to be reported to the Asset Manager directly for resolution. Asset managers will take corrective action if the lease agreement does not identify the landlord as responsible for the issue. However, if the lease agreement does indicate that the landlord is responsible, the Asset Manager will contact the landlord to take corrective action. During interviews with Asset Managers it was stated that one risk area is that some leases do not define all landlord repair responsibilities.

Inspections

Real Property had a process in place to ensure RCMP owned facilities and housing are regularly inspected to assess the condition of the building, and identify any maintenance work required. Interviews with Asset Managers noted that there is limited national guidance as to how this process needs to be carried out, with each region having a different approach to frequency. In some regions the inspections are performed annually while in others they are done on a bi-annual basis. While these inspections are focused on assessing the condition of the building, they include reviewing elements related to health and safety (e.g. condition of smoke/carbon dioxide alarms, tripping hazards, water leaks, condition of wooden exterior structures). The policy centre for real property identified that the development of national guidance for building inspections, including environmental health hazards, is underway. Audit testing of inspections conducted for member housing was carried out. Results indicated that 28 of 33 (85%) of the RCMP owned housing units reviewed had evidence to support that such an inspection had taken place recently. For leased facilities, the landlord is required to maintain the building so these inspections are not the responsibility of the RCMP and were not assessed as part of this testing.

There is a process in place to prioritize health and safety projects and repairs. When Asset Managers carry out building inspections, a Building Management Plan (BMP) is developed that identifies the various projects that need to be completed to maintain the facility. A prioritization process is used to determine projects to be completed based on available funding. A prioritization tool was developed by NHQ to rank projects by allocating more points to a project based on health and safety impacts to occupants. This allows projects with a major health and safety impact to be prioritized as part of the BMP process. Unexpected repairs have their own funding envelope and are not included in BMPs.

Processes and procedures related to RM housing were not always clear. Members who identify health and safety issues within their housing unit report them to their Detachment Commander and the responsible Asset Manager within divisional Real Property. Interviewees indicated that in some regions, roles and responsibilities, building and evacuation standards, and ways to communicate hazards (and mitigation strategies) to tenants were inadequate. While residents of a particular housing unit may identify or become aware of a hazard during their residency (e.g. presence of asbestos), there is no formal process to ensure that this information is communicated to the next tenant of that property. The absence of a process presents a risk given the higher turnover of residents in some regions (e.g. Northern locations with shorter posting periods). In addition, detachment commanders that are new to their role may also lack aw

Building inspections for Canada Labour Code Part II compliance are conducted by OSOs in each division. Interviews identified that in addition to the inspections described above conducted by Asset Managers, OSOs also conduct building inspections for Canada Labour Code Part II compliance in each division. While these inspections are not a formal responsibility of OSOs, they are carried out to complement WPHSC inspections and leverage the OSO's expertise in occupational health and safety for a more in-depth inspection than the WPHSC would be able to complete. While each division noted that inspections are taking place, the frequency of inspections differed. For example, some OSOs reported inspecting all workplaces within a two-year timeframe. Citing resource limitations as a constraint, OSOs in other divisions only completed inspections when needed, as opposed to having a specific schedule. There is no clear guidance in policy with respect to how often inspections need to take place, resulting in divisions identifying their own inspection schedules according to their capacities.

Hazardous Occurrence Reporting

There is a process in place to report health and safety incidents. A separate process, not directly related to facilities management, was in place to report health and safety incidents. Supervisors of employees that experience a health and safety incident are required to complete a Hazardous Occurrence Investigation Report (LAB1070 form), which documents the incident. This form is reviewed by the facility's WPHSC to ensure it is complete and identifies actions that can be taken to prevent future occurrences. The form is then provided to the Division's OSO for review and entry into HRMIS. For facilities without a WPHSC, the form is sent directly to the OSO. This allows the OSO to identify significant occurrences and report them to Division management as necessary.

Hazard Prevention Program

Awareness regarding Occupational Health and Safety's hazard prevention program was limited. The OSM included reference to a Hazard Prevention Program, which described various steps RCMP units can follow to identify relevant risks in the workplace and mitigate those risks. However, during interviews it was noted that awareness of the Hazard Prevention Program was limited. The OSM Chapter 16 Hazard Prevention Program includes a hazard recognition, assessment and control process and includes links to a guide, a tool and a database. The purpose of this program is to assist RCMP units/ facilities in identifying potential hazards, controls that need to be in place to reduce risk, and remaining residual risks. Interviews with high risk units* indicated a limited awareness of this program and that the tool was not being used. Instead, units reported that they identify and mitigate workplace hazards based on their experience and training which does not typically involve formally documenting all workplace related hazards. Interviews with the Occupational Health and Safety Branch (OHSB) policy centre and OSOs confirmed that awareness of the Hazard Prevention program was limited. The policy centre stated that resource limitations prevented them from taking a more active role in rolling out this tool.

* High risk units refer to those who the audit team determined, in consultation with subject matter experts, as those units who may encounter increased risk in the workplace due to the nature of their activities or training.

Testing for Environmental Health Hazards

Inconsistent testing for environmental hazards across regions. The audit found that processes for testing for environmental hazards are inconsistent across regions. Some regions provided evidence that they have formal environmental testing plans and that they were actively testing for various hazards and recording the results of this testing. Atlantic Region had documented testing plans for asbestos, radon and potable water contaminants as well as a summary report of the results of their testing in various locations across the region during the audit's scope period. However, other regions indicated that documented environmental plans do not exist and environmental testing is more limited. For example, some regions utilized a risk-based approach with testing limited to potable water in known high-risk areas and did not have a formal approach to radon testing.

Varying levels of documentation relating to testing. In addition, not all regions had documented evidence of the results of their testing and responsibility for subsequent steps to testing were not formally documented. This may increase the risk that these responsibilities will not be fulfilled. For example, if an environmental hazard such as asbestos is detected, building occupants should be made aware of necessary precautions that should be undertaken. (e.g. avoiding activities that would disturb the material such as renovations). Not having a formal process or assigning responsibility to inform the current and future occupants of the presence of this threat increases the risk that occupants may be unnecessarily exposed to known hazards. During interviews with Asset Managers and Environmental Specialists the differing approaches were described as being a result of resource limitations and insufficient policy direction relating to testing requirements.

Results from environmental testing performed by service providers are not always shared with the RCMP. Interviews with RCMP Environmental Specialists identified that while in some cases service providers may perform environmental testing on RCMP facilities, the results from these tests were not always shared with the RCMP. In Atlantic region and NHQ, the service provider performs environmental testing and communicates the results to the Regional Environmental Services group. These results were integrated with the environmental testing in those regions. In Pacific region, it was noted that while the service provider was performing environmental testing on RCMP facilities, what locations, if any, were being tested and the results of that testing were not being communicated to RCMP Environmental Specialists during the timeframe of the audit. This increases the risk that the RCMP is not aware of all hazards detected in its facilities.

Policy guidance around environmental testing is under development. During the timeframe of the audit, national policy guidance around testing for environmental health hazards was under development. The audit found that efforts were underway to establish a national drinking water program, national asbestos policy, and national radon program. These policies were still in draft form at the time of the audit. During interviews with Regional Directors, the audit team was informed that while there may be a desire for consistency across the country in how hazards are handled, some flexibility is needed as roles and responsibilities, underlying regional structures, and regional circumstances (e.g. geography, building size, environmental sources) could contribute to regional differences in how hazard testing is performed and recorded. For example, potable water is a complex area that depends on location, geology, and facility-specific circumstances. As a result, a testing plan designed for one region may need modification for application in a different region.

Information Management

The process for documenting environmental issues is regionally-based. Regional Environmental Specialists reported that information relating to most environmental hazards was not centralized, with information being recorded in a variety of different databases due to there being no clear guidance on where to store this information. Having information in different databases was described as inefficient by interviewees, noting that this requires looking at multiple data sources before taking action. In addition, it was noted that in some cases information pertaining to environmental testing may have been lost as it was not clear if or where it had been stored. As a result, this increases the risk that information on what testing took place and the results of that testing may not be effectively recorded and made accessible, limiting the ability of Environmental Specialists, Asset Managers, OSOs and Detachment Commanders to be fully aware of hazards in RCMP facilities.

The retention and tracking of environmental hazard information may be a risk area. While challenges with information management were noted with respect to radon and potable water, a more structured approach was in place for asbestos. A national asbestos inventory of RCMP-owned buildings including both workspaces and housing units is maintained by the Environmental Policy Centre. This inventory identifies whether a facility has been tested, if asbestos had been identified, and whether an Asbestos Management Plan exists. However, interviews with Environmental Specialists indicated that similar tools to document and track other environmental hazards were lacking. Furthermore, the audit team was also informed that formal processes for archiving pertinent historical information was also lacking. This limited the ability of the Environmental Specialists to use historical test results to perform trend analysis.

Conclusion

The audit found that the RCMP has processes and procedures in place to identify and prioritize health and safety risks in RCMP facilities; however, there are opportunities for improvement. More consistent inspections, environmental testing, and information management would promote better mitigation of health and safety risks to RCMP employees, contractors, and the public.

Why these findings are important

Processes to identify and mitigate health and safety hazards needs to be followed in order to ensure their effectiveness. For example, not carrying out inspections and testing, or carrying them out in an inconsistent manner increases the risk that hazards will not be detected or communicated appropriately, leading to possible health and safety incidents. In addition, an effective information management strategy that includes retaining and recording test results is important for historical analysis, documenting compliance to policy requirements, and for the identification of potential future health and safety risks. This information should be accessible to be useful to decision makers and is an important part of demonstrating the organization has applied due diligence for environmental health risks.

Recommendation 2

The Chief Financial Officer, Corporate Management and Comptrollership should enhance monitoring of regional activities relating to environmental health hazards to ensure key aspects of policy and national guidance are consistently applied across the RCMP by:

- assessing compliance with environmental testing requirements (once national policy and guidance have been updated).

- ensuring appropriate information retention and communication of testing results and related mitigation.

3.3 Monitoring and Reporting

- Observation

- A variety of monitoring mechanisms were in place to track and report on health and safety issues and incidents. Opportunities exist to enhance and standardize the monitoring of workplace inspections to help mitigate the risk that health and safety concerns go undetected.

Health and Safety Monitoring Mechanisms

Health and safety issues reported to the NSCC are monitored. For RCMP facilities with access to the NSCC, health and safety risks that are reported to the NSCC allow the issue to be tracked. When issues are reported to the NSCC, a ticket is created to allow the issues to be recorded and monitored until resolution. Asset Managers are provided daily logs of calls made as well as the status of the issue, allowing them to monitor reported issues. Asset Managers reported to the audit team that the formatting of call log data provided from the NSCC is not useable for trend analysis without significant manipulation. While monitoring of issues reported to the NSCC is possible, it was noted that there was no central database to track these hazards which impacts the Asset Managers' ability to monitor them over time for trends. In the case of member housing and buildings not covered by the NSCC, issues are usually reported by employees directly to the detachment commander/divisional real property and individual landlords respectively.

The majority of WPHSCs discuss LAB1070 incident reports. Health and safety incidents which occur are expected to be recorded on LAB1070 forms and WPHSCs are responsible to monitor these forms to determine whether actions can be taken to prevent further incidents. To assess whether this monitoring was occurring, the audit team reviewed the meeting minutes from a sample of 25 WPHSCs in RCMP facilities. As depicted in Figure 4, the majority of committees had meeting minutes with evidence that LAB1070s were being discussed.

| Evidence of LAB1070s discussed | No evidence of LAB1070s discussed | |

|---|---|---|

| Percentage | 88 | 12 |

Meeting minutes also demonstrated that committees took steps to identify, track, and remediate identified health and safety issues. Minutes revealed that issues were noted, they were assigned to a specific committee member, and then tracked through to resolution in subsequent meetings. Interviews with WPHSC Co-Chairpersons further confirmed that LAB1070 forms are discussed, recommendations and resolutions are sought where possible, and incidents are recorded in HRMIS as required by the OSM. Depending on the nature of the issue, this can involve communication with the Asset Manager for the facility if the incident was tied to a repair or maintenance issue. This allows the Asset Manager to be aware of issues that occur related to facility maintenance so they can be prevented in the future.

Inspection monitoring mechanisms

Limited formal monitoring for workplace inspections at the Divisional or national level. While WPHSC/Rs are required to inspect the facilities they are working in, a formal process to monitor whether the inspections were occurring at the Divisional or national level was not identified. During interviews with OSOs it was noted that monitoring of workplace inspections was the responsibility of the manager or Detachment Commander responsible for the workplace. Interviews with Division management noted a reliance on the OSOs to inform them of issues related to health and safety in their Division, but likewise did not identify specific processes to assess compliance with inspection requirements. As noted in Criteria 1, questionnaires to Detachment Commanders identified a lack of awareness regarding roles and responsibilities related to health and safety in facilities. This includes appointing a health and safety representative and ensuring workplace inspections take place. Interviews with the Occupational Health and Safety Branch Policy Centre confirmed that this was a risk area, but stated that resource limitations limited their monitoring activities.

Conclusion

The audit found that there are opportunities to improve monitoring over health and safety inspections. A lack of inspections being carried out limits the ability to detect health and safety hazards and prevent incidents. Monitoring can improve compliance in completing the workplace inspections as required and may identify where WPHSC/Rs are unable to carry out or are unaware of their responsibilities in this area. Not monitoring whether these inspections are being carried out limits management's ability to detect issues and provide course correction and guidance where necessary.

Why these findings are important

Inspections are an important mechanism to identify health and safety issues and ensure that where possible, remediation takes place. Monitoring over workplace inspections will allow management to identify any areas of non-compliance that need to be addressed to ensure employee safety.

Recommendation 3

The Chief Human Resources Officer should enhance the occupational health and safety program by implementing monitoring requirements over workplace health and safety inspections.

Appendix A – Audit objective and criteria

- Objective

- To assess the adequacy of the RCMP facilities management framework in ensuring the health and safety of employees.

- Criterion 1

- A facilities management framework is in place that takes into consideration the occupational health and safety of employees.

- Criterion 2

- Processes and procedures are in place across the RCMP to identify health and safety risks and address related issues within facilities to ensure compliance with policy.

- Criterion 3

- Monitoring is in place to ensure that health and safety risks are tracked, reported and addressed.

Appendix B - Management action plan

| Recommendation | Management action plan |

|---|---|

| Agree. In 2021, the Real Property Management Branch and Regions ranked environmental health policy priorities that were required. Existing resources were assigned to the identified priorities in the National Environmental Policy Centre. In March 2022, the Real Property Management Branch issued policy direction for testing and monitoring requirements for both asbestos and potable water. Additionally, internal consultations are ongoing with drafts of testing and monitoring requirements for radon and legionella. These are expected to be finalized and published in the fall 2022. To better clarify testing requirements and communicate policy changes to stakeholders, the Real Property Management Branch is drafting a National Call Letter to be completed in the fall 2022. The regular distribution frequency of the Call Letter will be confirmed upon completion of the drafting exercise. This document will summarize all testing and monitoring requirements and priorities for RCMP occupied space (including housing and leased space) in one comprehensive document thereby better communicating policy priorities with relevant stakeholders. Lastly, updated Human Resource Plans and staffing actions are ongoing to increase the complement of environmental specialists both in the National Environmental Policy Centre and the regions. These additional resources will enable the National Environmental Policy Centre to update older policies and introduce new policies and guidance. New resources added within the regions in late 2022 and 2023 will facilitate the appropriate testing and monitoring required from the new policy direction. Occupational Health and Safety Branch is in the process of hiring a certified hygienist who will provide direction, advice, and guidance on legislative compliance requirements and hygiene standards to support the development and implementation of environmental process in consultation with Real Property. Completion Date: Radon Policy Bulletin – Fall 2022 Position Responsible: Director General of Real Property Management and |

| Agree. To complement the National Call Letter noted earlier, the National Environmental Policy Centre is implementing the use of Key Performance Indicators to monitor the implementation and effectiveness of RCMP policy instruments associated with Real Property related environmental health. Results of testing and monitoring compliance will be tracked and reported. These results will be shared with the National Policy Health and Safety Committees on a quarterly basis. The National Environmental Policy Centre has engaged with Records Management to propose a longer retention period for health and safety documents extending to 30 years beyond the life of facilities. Real Property Management is piloting the use of GCdocs as a document management system. Real Property intends to broaden the use of GCdocs for real property personnel to retain information in corporate systems. Real Property Management will collaborate more closely with regional representatives regarding communication prior to, during, and after environmental testing has been completed to ensure that the appropriate personnel are informed. The new resources referenced above will support improved communication and national oversight of policies and guidance. Mitigation efforts will entail a multipronged approach of regular meetings, clear policy bulletins, and a comprehensive National Call Letter capturing all current requirements in one document. Completion Date: Key Performance Indicators established for existing policies – Fall 2022. Position Responsible: Director General of Real Property Management and |

| Agree. Currently Workplace Health and Safety Committees and representatives perform workplace inspections at each location on a monthly basis using a recently revised checklist tool (February 2022). This information is tracked at the divisional level and OHSB receives this information annually. Greater oversight is necessary to identify areas which are not fully compliant and ensure that comprehensive tools are available to support a consistent national approach. We will establish a systems approach to increasing visibility into the existing workplace inspection process to ensure greater compliance and determine a process for monitoring compliance and supporting a consistent approach to the inspection process. This will include the development of a survey tool that will be administered on a quarterly basis to monitor that inspections are conducted, action items identified, corrective action planned/completed. In addition, this will allow visibility on progress, gaps and allow opportunities for improvement. This survey tool will be used to collect and compile data for reporting back to divisions on any issues and will also be used for the preparation on annual Divisional Safety Performance Report Card. Completion Date: Key Performance Indicators: Position Responsible: Director General of Occupational Health and Safety Branch |

- Date modified: